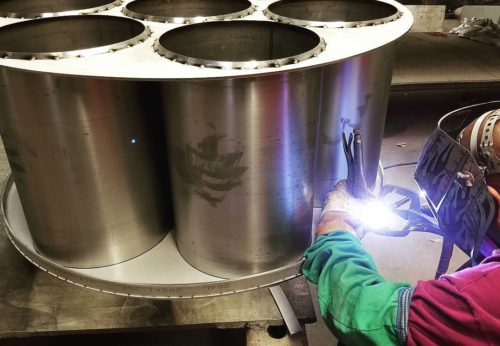

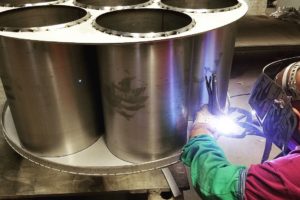

Welding is one of the most fundamental manufacturing processes, affording an efficient, versatile, and cost-effective method of joining two pieces of metal. Though there are many different techniques, each presenting its own benefits, the core concept of each process is the same—a certified welder applies controlled pressure and heat to create a firm bond between two components.

Despite rapid advancements in machining and metalwork processes, welding remains a mainstay of virtually every industry that relies on metalwork. As common as it is, however, it requires a high degree of technical ability.

An experienced professional can not only guide you toward the correct welding process for your project, but also execute that technique with precision and skill.

See our full gallery for videos & past projects in Welding.

GalleryMost Common Types of Welding Services

The techniques are mainly differentiated by the equipment and gases used, as well as by the characteristics of the resulting bonds. Three of the most common options are:

- Tungsten Inert Gas (TIG), also known as Gas Tungsten Arc Welding (GTAW)

- Metal Inert Gas (MIG), also known as Gas Metal Arc Welding (GMAW)

- Shielded Metal Arc Welding (SMAW), also known as Stick Welding

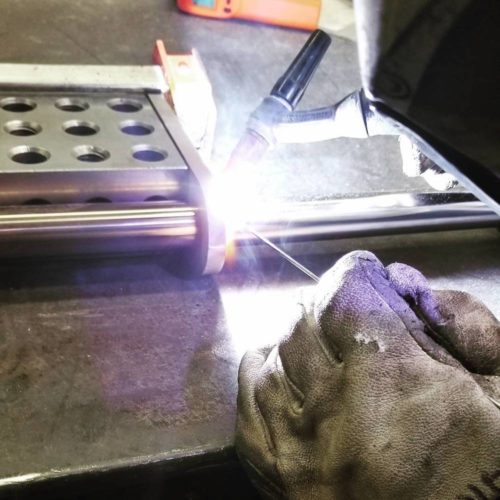

TIG Welding. Extremely versatile but requires a high degree of technical competence. The welder must simultaneously feed a rod while also operating a TIG torch. The electrode on this torch heats the base metal to form precise weld beads that hold the two pieces together.

This is one of the most popular techniques today, allowing for clean, precise welds with high degrees of purity. It also creates an aesthetically pleasing finish thanks to the beads, and it is useful for many industries and applications due to the range of suitable materials—which includes a wide range of conventional metals and alloys like stainless steel.

MIG Welding. A comparatively simple technique that is nonetheless valued for its ability to create extremely strong bonds with minimal waste. The technique involves feeding an electrode through a welding gun to form an electric arc between the base material and the electrode. This arc is what heats the material sufficiently to melt and join two pieces.

This method is popular in the automotive and maritime industries because of the strength of its bonds. It is also useful for joining thinner materials, especially when using bare wire rather than a flux core.

SMAW. One of the more traditional techniques, although it still retains benefits for many modern applications. It is a lower-cost, portable alternative to the other methods, and it can be used for trickier repairs and installations—such as rusted metals—that would prevent a MIG or TIG approach.

Like MIG, it uses a consumable electrode that is melted by an electric arc. Unlike MIG or TIG, however, SMAW does not require the use of a shielding gas, which is otherwise used to protect the weld puddle as it forms. SMAW does create a byproduct layer of slag that must be removed, which presents an additional step when compared to other techniques. Otherwise, it is a relatively simple process that holds its weight with heavy industrial jobs.

Industry Leading Metal Welders

Because our services are so ubiquitous, we have experience working with a wide variety of industries. Some of our most frequently served sectors include:

- Institutional equipment

- Construction

- Manufacturing

- Aerospace

- Robotics

- Agriculture

Custom Welding Projects

The success of any project depends heavily on the ability and knowledge of the welder. No matter how complex your needs, our skilled team of fabricators will work with you to identify and apply the techniques that best suit your materials, budget, and timeline.

Contact us to learn more about the advantages of collaborating with an industry-leading shop on your next metalwork project.