Kitting is a process—often performed by a third-party logistics (3PL) company—that involves compiling the individual parts necessary for a product into a complete kit and delivering it to the designated assembly station or center. For product manufacturers and distributors, the process can streamline production operations—such as product assembly—and facilitate better product management, resulting in a reduction in production costs and an increase in profits.

The Benefits of Custom Kitting Services

Depending on your organization’s requirements, our services are likely to present a number of benefits, such as reducing:

- Product processing times

- Downtime in assembly operations

- Operator handling and motion time

All of these benefits translate to more efficient and cost-effective production workflows.

Our Kitting Process

At Precision Machining & Fab, every kitting project we take on goes through the following steps:

- Meeting with the client: We consult with the customer to determine the parts they need, the part quantities required, and the type of kit necessary.

- Planning the project: Our team works in tandem with yours to determine the crate size, the component layout within the kit, the kit weight, etc.

- Presenting to the client: We present customers with an initial project plan, and they may offer feedback or grant approval.

- Executing the project: We create, package, and prepare parts for shipment.

- Shipping: We arrange shipping for the complete kits. We offer standard, freight, and third-party (on behalf of the customer) shipping options, as well as pelican and custom shipping containers.

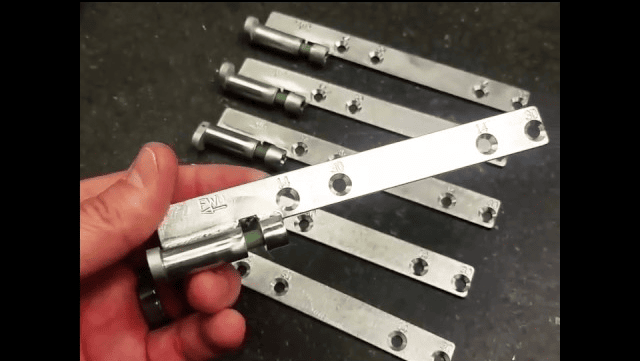

Our Kitting and Assembly Services

Our expert team has the skills and knowledge to provide any customer with a kitting solution that meets their unique needs. Our in-house kitting capabilities are available as full-service orders or a la carte and include:

- Machine cutting and welding pieces

- Inserting parts into foam cases for protection during storage and transport

- Producing specialty installation tools

- Shipping to customers’ assembly or distribution centers

- Waterjet cutting foam for separate projects

We also offer hardware installation and assembly services for:

- Riveting

- PEM® nuts assemblies

- Nut plate assemblies

- Screwed/bolted assemblies

- Welding assemblies

Combined with our manufacturing capabilities, these additional services allow us to control the quality of the individual components and products we produce. We work closely with our customers to maximize efficiency and ensure finished assemblies fit the required part specifications and seamlessly integrate into existing products and equipment.

Some of the industries we serve with our kitting and assembly services include:

- Aerospace

- Electronics

- Optics

- Oil and gas

Partnering With Us for Kitting and Assembly Solutions

At Precision Machining & Fab, our team is committed to meeting our customers’ needs and exceeding their expectations for quality with fast turnaround. By partnering with us as a provider of your fulfillment services, our customers can take advantage of:

- Fast manufacturing and delivery times (crating solutions take an average of two weeks)

- Expert layout design and assistance services

- Full parts inventory accounting

- Extensive part and kit quality control and inspection services (including full or sampling inspection)

Interested in learning more about our assembly and kitting services or partnering with us on your next project? Contact us today to speak to a knowledgeable representative.