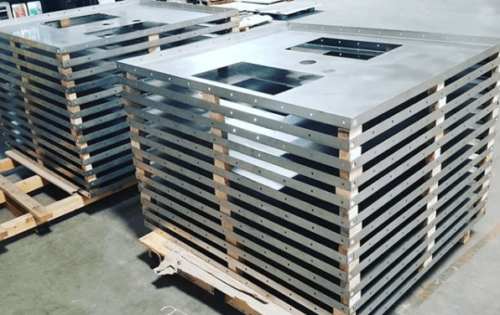

Custom sheet metal fabrication services play a vital role in an expansive range of production processes. The team at Precision Machining & Fab has the necessary tools and expertise to accommodate nearly any sheet metal fabrication project. As a contract manufacturer, we have helped numerous customers across a wide array of industries to drive down costs and drive up quality.

Though waterjet and laser cutting is our focus, Precision also provides design, production, and consulting services. In addition, we operate a fully equipped machine shop from which we are able to provide quick turnaround prototypes for large-scale orders.

Our fabrication capabilities include:

- Stamping

- Punching

- Forming

- Bending

- Anodizing

- Plating

- Painting and powder coating

We apply time-tested manufacturing techniques and cutting-edge equipment to increase the value of every unit we produce, from aerospace components to building products. Our staff includes skilled fabricators and AWS-certified welders with the skills to deliver a level of craftsmanship that eclipses the minimum standards of quality and integrity demanded by the industries we serve.

The Precision team believes that quality is more than a process requirement—it’s part of the culture integrated into every area of our organization. Evidence of our deep-rooted commitment is included in the ISO 9001 and AS 9100 certification standards maintained by our facilities. We are also set up to provide compliance with additional industry standards and regulations, including Mil-Spec.

See our full gallery for videos & past projects in

CNC Sheet Metal Fabrication.

GalleryTypes of Sheet Metal Fabrication Processes

The sheet metal fabrication process is complex and makes use of a wide range of different processes. The various types of sheet metal fabrication processes include:

- Cutting. Saws were the traditional equipment used for cutting, but more innovative methods such as waterjet, plasma, and laser cutting have become the norm in more advanced shops because they provide cleaner cuts that require less secondary finishing.

- Folding. The use of a brake press and specially designed dies combine to form the necessary creases in a metal sheet through pinching.

- Machining. This term covers almost any subtractive manufacturing process that removes material from a workpiece. Machining may include lathes/turning machines or milling machines with various tools, including drills and other cutting tools. The range of motion of the cutting head relates to the number of available axes on the machine.

- Punching/blanking. After creating a die to a specified size and shape, the die is attached to a hydraulic press that cuts the desired shape out of a piece of sheet metal.

- Shearing. This process cuts a sheet of metal along an extended line.

- Stamping. Like punching or blanking, stamping uses a specially designed die to create the desired shape. However, in contrast to punching, stamping causes the desired shape to be raised from the piece in relief rather than creating a penetration of the shape through it.

- Welding. Welding joins two metals by melting and fusing the two pieces together at a joint. There are several different methods of welding.

These processes—individually or in combination—make up the majority of methods used in sheet metal fabrication.

Wide Range of Materials Used

Though a wide variety of materials are available for sheet metal fabrication, the two most common are stainless steel and aluminum. Each option has advantages for various manufacturing applications.

- Stainless Steel. This is used in sheet metal manufacturing because its properties combine strength, durability, corrosion resistance, and easy cleaning. Applications such as food processing, storage, medical, and certain manufacturing environments—where the absence of corrosion and contamination are essential—are common applications for stainless steel.

- Aluminum. It’s lightweight, paired with favorable compressive and tensile strength, makes aluminum a popular material. Applications that use aluminum make up the broadest array of commercial and industrial products, including those in the automotive, aerospace, packaging, construction, home appliances, electronics, food and beverage, and music industries, among many others.

- Additional Alloys. Additional alloys prized for various properties that support specialized applications include copper, nickel, brass, and titanium. In some instances, the process might include using precious metals like gold, silver, and platinum as well.

Wide Variety of Industries Served

The range of industries served is broad, including:

- Manufacturing

- Food & Beverage

- Storage & Warehousing

- Aerospace

- Automotive & Transportation

- Packaging

- Construction

- Music

- Electronics

Sheet Metal Fabrication Services

Custom sheet metal fabrication plays a primary role in the manufacturing of a wide range of products for industrial and commercial applications. The variety of processes included make it possible to form almost any part or component. Working with an industry leader helps ensure a high level of part quality while keeping costs low.

Contact us to learn more about the various manufacturing solutions Precision Machining & Fab can provide to your organization.