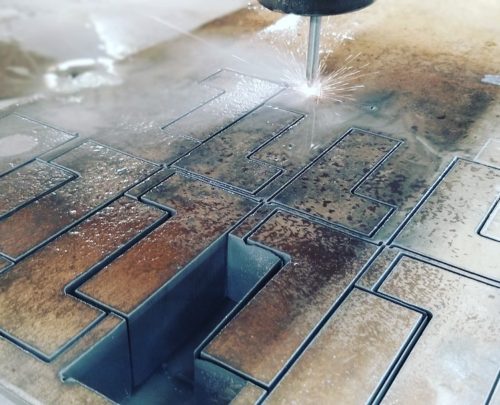

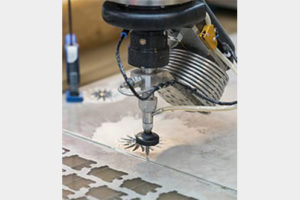

From our very beginning of Precision Machining & Fab, precision waterjet cutting services have been a central part of many of our products. As we have grown, Precision Machining & Fab has invested in the best technology in waterjet cutting systems. With nine individual systems, we can respond to production demands as small as a single prototype, while also working on projects that continue for many months and are large in volume.

Our Waterjet Cutters

These meticulous waterjet cutting systems give us unparalleled versatility. They can cut materials as thin as 0.001”, up to thicknesses at 12” and they work within an envelope ranging from 0.06” to 160” in width and 0.06” to 320” in length. With these systems, we can create edge finishes in the one to five range, while maintaining tolerances a close as ±0.005”.

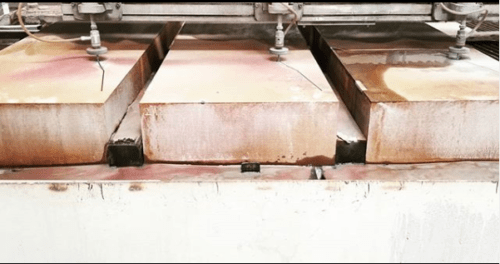

The efficiency of our machines is remarkable as well, with a pressure of 5,000 to 92,000 PSI, enabling the water to pump out at speeds as high as 600” per minute, depending on the thickness and type of material. The machines are so meticulously automated that they can run with lights out. They reduce scrap waste with kerf widths that are as small as 0.005”. Our machines along with our advanced nesting software allow us to maximize material usage, lowering overall costs.

See our full gallery for videos & past projects in

Waterjet Cutting.

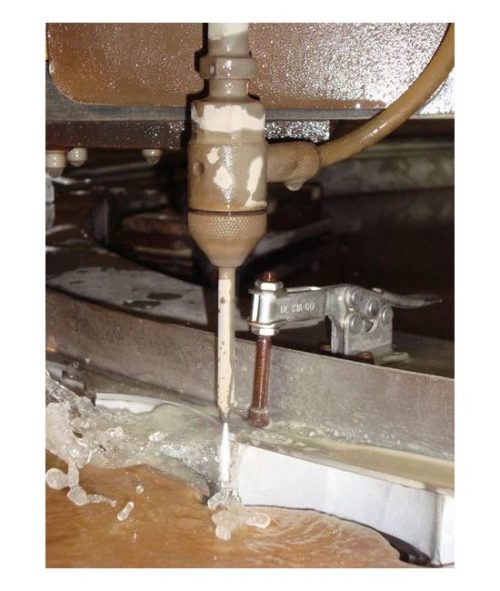

GalleryFor harder and thicker materials, we use abrasive waterjet machining that works with pieces as large as 120” by 300”. These machines can cut through materials as thick as 10”.

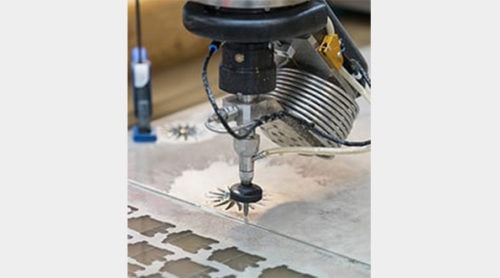

At Precision Machining & Fab, we are one of the few facilities worldwide with a double-head machine. We are the only manufacturer in California who offers the new Dynamic Waterjet technology, which practically eliminates taper with state-of-the-art 5-axis cutting heads that are computer controlled. Contact us directly for more information about the benefits of this technology.

Wide Variety of Materials

Waterjet machines work well on a wide variety of materials. Some examples of these are:

- Composites (reinforced plastics)

- Metals

- Metal alloys

- Glass

- Stone

- Concrete

- Rubber

In fact, it’s effective at cutting just about anything, with the exception of extremely hard ceramics and tempered glass.

When working with a wide range of materials that are softer, such as textiles, rubber, foam, or food, non-abrasive waterjet cutting is used. In this method, a stream of water pumps through a diamond, sapphire, or ruby opening at ultra-high pressure. This creates a cutting stream of water that moves at over twice the speed of sound, giving very high cutting rates. For harder materials, like stainless steel, abrasive waterjet cutting uses a mixing chamber to combine high pressure water and abrasive particles into a powerful cutting stream.

This gives us a wide range of versatility in cutting ability. This method can be used to cut glass into window panels, optic lenses, or even art installations. It is common in the food industry, eliminating the risk of cross-contamination that is inherent in blades.

Industries Served

This precise and efficient cutting method has applications throughout a wide variety of industries, such as:

- Automotive

- Aerospace

- Oil & Gas

- Energy

- Agriculture

- Transportation

- Artwork

- Architecture

Benefits of Waterjet Cutting Services

Waterjet cutting works in ways that heat or friction based methods simply cannot. It significantly reduces part stress, and because it doesn’t heat the material, it eliminates thermal distortion and hardening that you see with flame cutting. In this way, it produces clean edges that need very little or even no secondary finishing work.

As a cold cutting process, waterjet cutting prevents interfering with the material’s structure, so metals can be cut without altering their properties. It also has minimal kerf, which reduces waste. The smooth edges it creates lower the need for secondary finishing. Its speed is five to 10 times faster than electrical discharge machining on materials under 1” thick.

Request a Quote for Precision Waterjet Cutting

Waterjet cutting is remarkable, adaptable, and extremely precise. At Precision Machining & Fab, we have invested in state-of-the-art technology to bring you the best of this method. Non-abrasive and abrasive waterjet cutting techniques can be used on an enormous array of materials with minimal waste.

For more information about the services we offer and to get a quote, contact us.