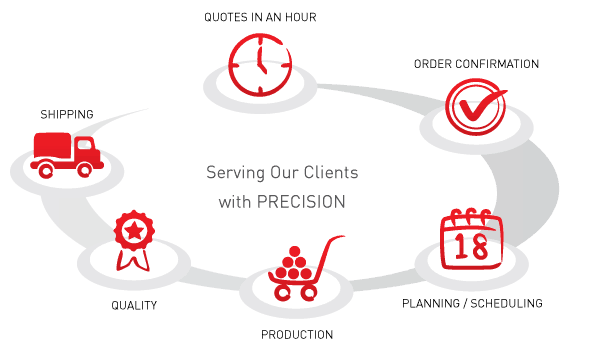

We take the idea of “Serving Our Clients with Precision” very seriously. It is more than just our slogan – it’s the philosophy of our company. Providing exceptional service is just as essential to our mission as any of our machines. By taking this proactive approach to service, we are committed to meeting your needs, exceeding your expectations, and earning your business.

What Makes Precision Machining & Fab Different?